Rhenium

Ultra-rare metal Strategic for superalloys in jet engines and catalysts; among the scarcest elements in Earth's crust.

Properties

Rhenium (Re): The Last Stable Metal Discovered

The history of rhenium is a long scientific quest: it is the last stable element to be discovered. As early as 1871, Mendeleev had predicted its existence, but isolating rhenium proved extremely difficult. After decades of failed attempts, German chemists Walter Noddack, Ida Tacke and Otto Berg announced its discovery in 1925. They found it as tiny traces in crude platinum and molybdenite ore, naming it after the Rhine river (Rhenus in Latin). Extremely rare and boasting the third‑highest melting point of all elements, rhenium became a key to modern aeronautics. Alloyed with nickel, it forms the superalloys used in aircraft and rocket turbines, allowing them to withstand extreme temperatures and pressures.

Key Applications

Market Data

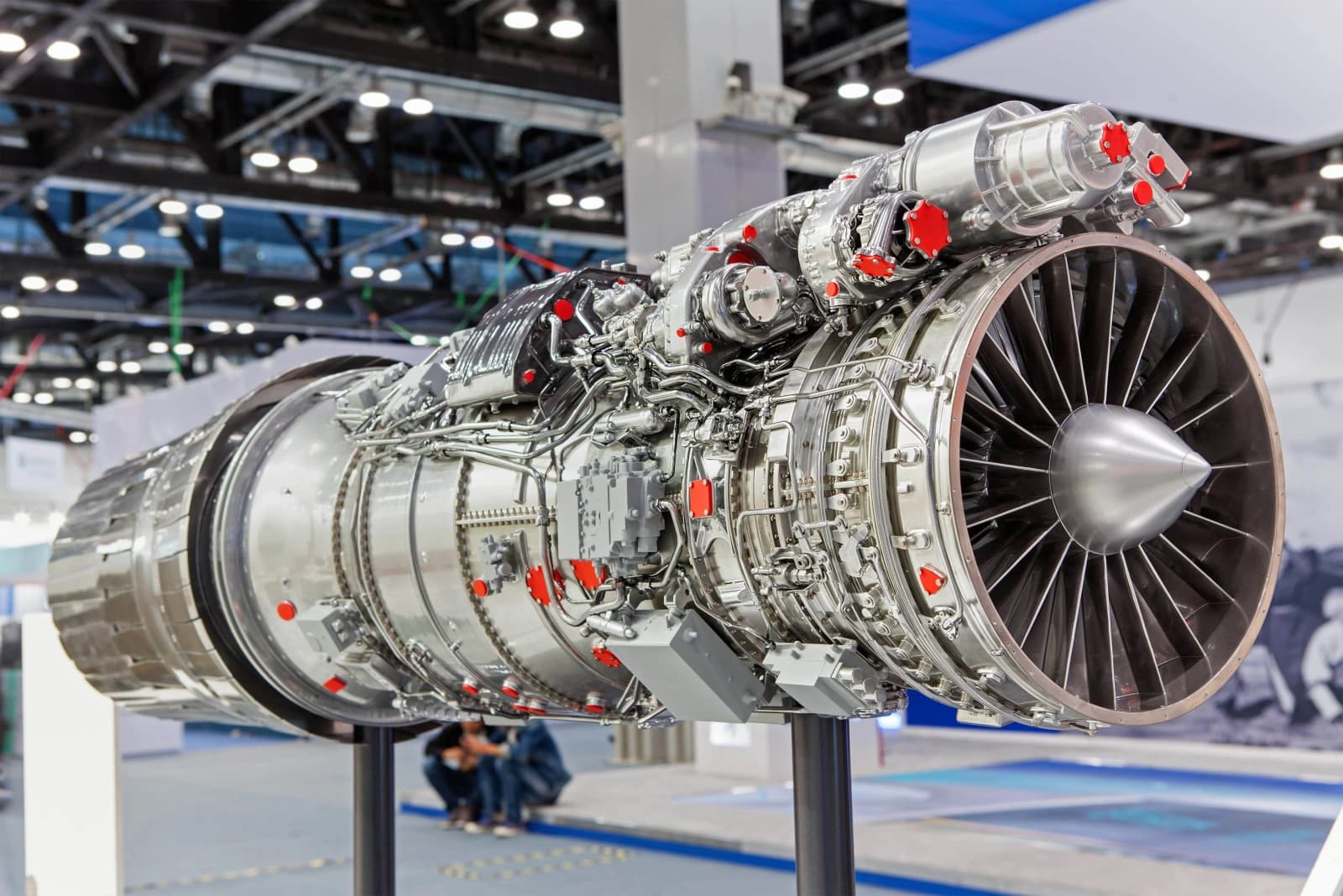

Rhenium (Re): The Thermal Shield of Aeronautics

Rhenium, the last stable element discovered, is the metal of extreme endurance. With an exceptionally high melting point, it is indispensable in the hottest, most demanding environments.

Strategic Applications: Nickel–rhenium superalloys for turbine blades in aircraft and rockets (civil and military), high‑temperature furnace filaments.

Industrial Interest: Investing in rhenium positions you in aerospace and space performance; it ensures the longevity and energy efficiency of next‑generation jet engines.

Risks & Substitutes

Extreme scarcity and byproduct production (molybdenum); high price volatility.

Substitutes/mitigations: optimized superalloys (less Re), Ru additions, ceramic‑matrix composites (CMCs) depending on application.

Dependence on aerospace/space; cyclical exposure.